I wasn’t happy with how much rust remained after the vinegar treatment, so I decided to give the vise a treatment with Evapo-Rust – my favorite rust remover.

I also decided that so little paint was left, I’d strip the remaining paint off, either with paint stripper or a wire wheel, depending on whether the paint had lead in it.

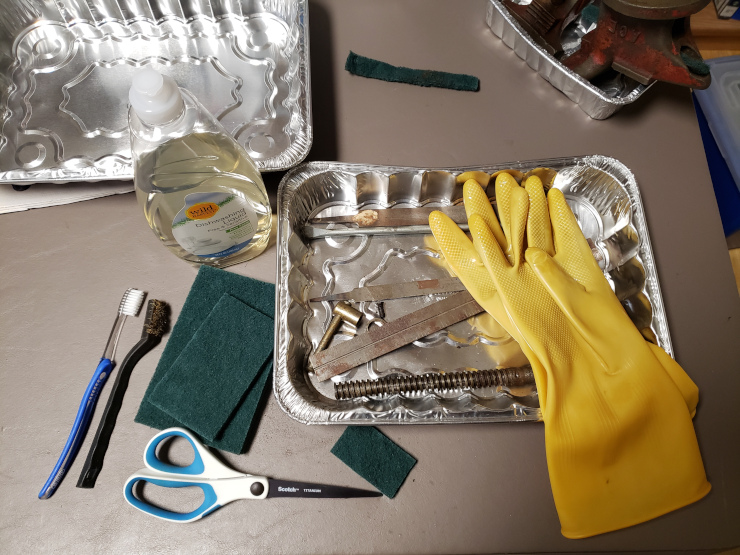

I decided to start by cleaning the parts of this vise the way I clean clock parts:

- Clean the parts with mild dish detergent, water, and a toothbrush. As an experiment I also used a brass brush, which was a bad idea: it removed a lot of lead-untested paint.

- Dry the parts with paper towels.

- Wipe the parts with paper towels, pouring isopropyl alcohol on them.

- Dry the parts again with paper towels.

I know water is a not the best because it can promote rust, but I don’t like working with highly flammable and toxic Mineral Spirits.

By the way, I tried using ScotchBrite heavy duty scouring pads for the really dirty vise parts. I cut the pads into parts that would fit into the nooks and crannies of the parts. It worked well.

Removing the rust

After cleaning and drying, I soaked the parts in Evapo-Rust. I also threw in a couple other rusty things I had lying around.

I left the parts in Evapo-Rust for a couple days while the rust simply melted off.

I then did the dish detergent and toothbrush cleaning and drying again, to remove the bits of residue.

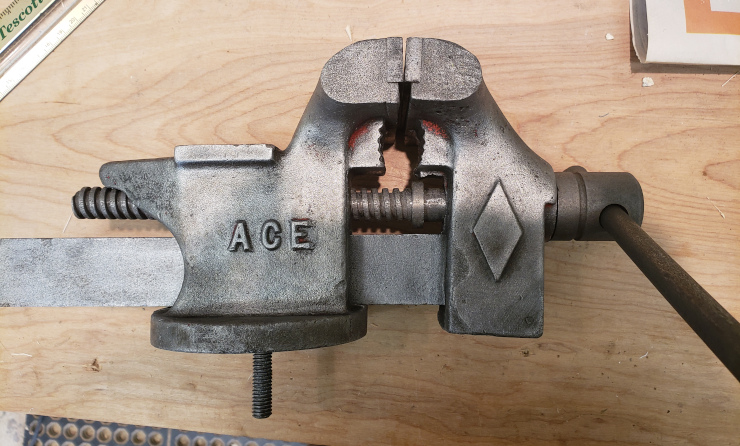

I’m so impressed with this stuff: look at the difference before and after the Evapo-Rust:

As you can see in the second photo, the rust is completely gone!

You can also see why you want to keep your tools clean and free of rust: years of rust had eaten pits into the steel.

The jaw parts of the vise were too large to fit in the aluminum trays I had, so after a hunt around the house I found the perfect thing: the liner of my office trash can.

I soaked the fixed end of the vise for a couple days, then did the same for the movable end.

While I was waiting for the rust to disappear, I happened to re-read the directions on the Evapo-Rust site: soak for an hour, rinse in water, repeat until no more rust comes off. So I didn’t have to soak parts for days after all.

It took about 5 soak-an-hour-then-rinse cycles until almost nothing came off.

After seeing the cleaned fixed jaw, I decided the brass brush was a bad idea: it removed a lot of the remaining paint. Paint that I might have wanted to keep, and might have contained lead! You can see that the movable jaw – which I didn’t scrape with a brass brush – has much more of its original paint.

Removing the paint

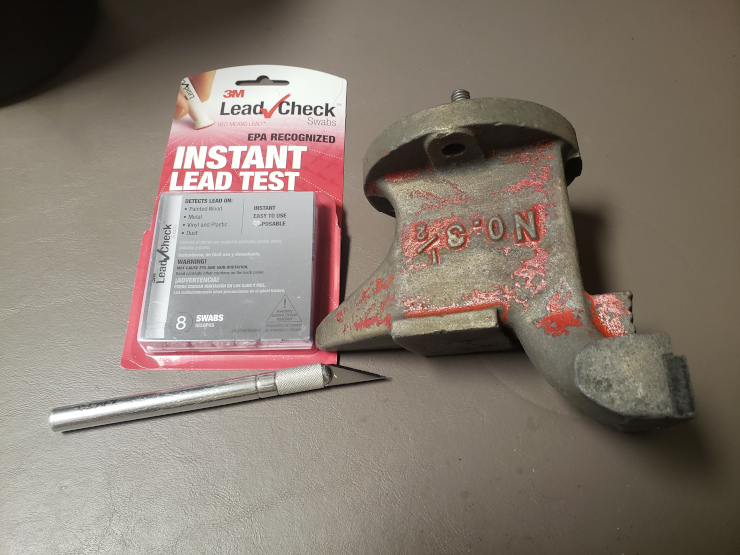

Now that the parts were clean and dry, I tested the paint for lead using a 3M Instant Lead Test kit. I should have done this at the start, but only recently re-read the instructions for the lead test kit: clean the area to be tested, then scratch the paint with a knife to expose un-weathered paint.

Now that I knew the paint was not lead-based, I used a few wire wheels and a hand drill to take off almost all of the paint. Had the paint been lead-based, I would have used paint stripper instead, to avoid throwing lead dust everywhere.

Once I scraped the paint off, I sprayed all the parts with WD-40 to prevent rust.

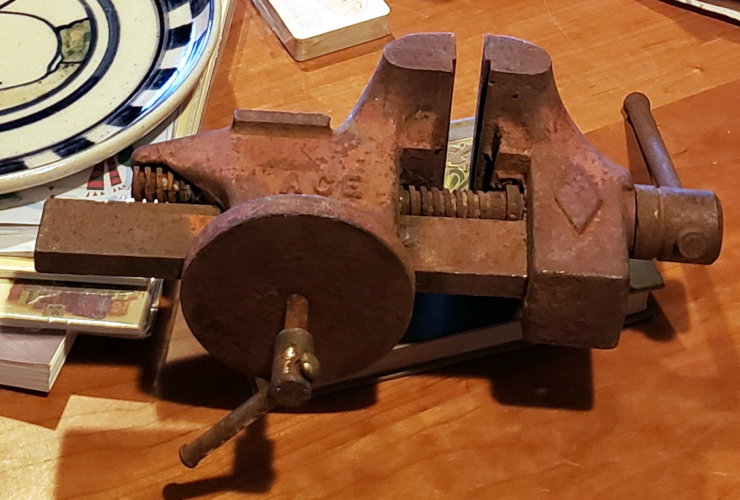

As a reminder, here’s what the vise looked like when I bought it at the garage sale:

Now that the vise is clean, I can start on the repairs to the vise… but that’s another post.