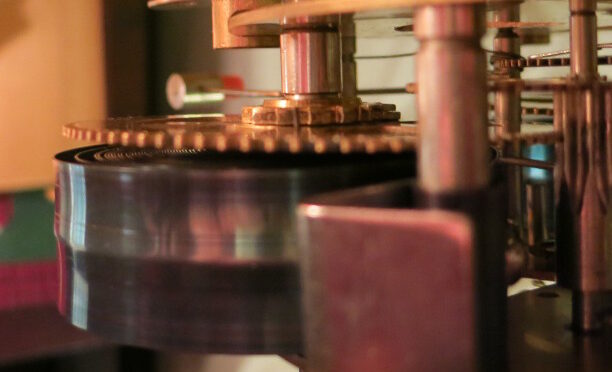

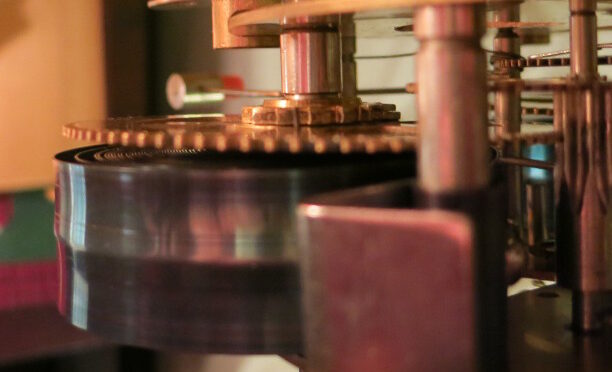

I just now learned how the great wheels – the mainspring gears – work, by finding they didn’t work correctly in my Korean clock. The strike train Tension Washer, that is supposed to hold the gear firmly against the ratchet, has come loose. …so I had to disassemble the clock, after it had run fine for over 11 days.

In my previous post I had set the pendulum length, regulated (adjusted the speed of) the clock, and set it running for a 30-day test, to see whether its springs still run the clock for its full 31 days. If they don’t I’ll need to replace the springs.

Continue reading Clock Repair 101: How the Great Wheel Works →

In my previous post about this clock I ordered a replacement pendulum suspension rod and bob, because the originals were missing. In this post I cut the suspension rod to length and adjust the speed of the clock, using audio recording to measure the timing of the tick-tock.

Continue reading Clock Repair 101: Adjusting the Korean Clock Speed →

Since I was making good progress on my first clock, I decided to haunt the antique malls looking for a second one to repair. I wasn’t really planning to buy a clock until I’d finished the first, but I found the perfect second clock to work on.

I found it in an antique mall in Hillsboro (Oregon). It’s a mantel clock – a Kitchen Clock – similar to my family Seth Thomas clock that is my eventual target for repair (once I know what I’m doing). It also fit the bill of a) not working well, and b) not worth a lot.

Continue reading The Second Clock: A Craft-Altered Ansonia Derby →

In my previous post I calculated the theoretical length of the pendulum my Korean 30-day clock requires. You may recall that the clock as I bought it had a broken pendulum suspension spring, and the pendulum parts – the suspension rod and bob – were missing. In this post I order replacement pendulum parts.

Continue reading Clock Repair 101: Ordering Replacement Parts →

Technical Writing and Self-Pubilshing