While waiting for its case to be repaired, my craft-altered Ansonia Derby clock has been running on a test stand – off and on for quite a while. I noticed that every great once in a while the count lever failed to drop into the 8 o’clock slot, causing the number of hours struck to be incorrect from then on.

The problem was that the count lever needed adjusting so the lever wouldn’t hang up on the walls of the slot it was dropping into. In this post I describe my adventure of adjusting (bending) the count lever.

I put off this adjustment for at least a year because I felt the count lever adjustment was fiddly. For one thing I’d found that the count wheel has significant backlash (wiggle): that is, if you pull the wheel counter-clockwise it moves about 1/2 of a slot relative to the normal situation, where the count wheel drags in the clockwise direction. (By the way, this count wheel moves in the counter-clockwise direction.)

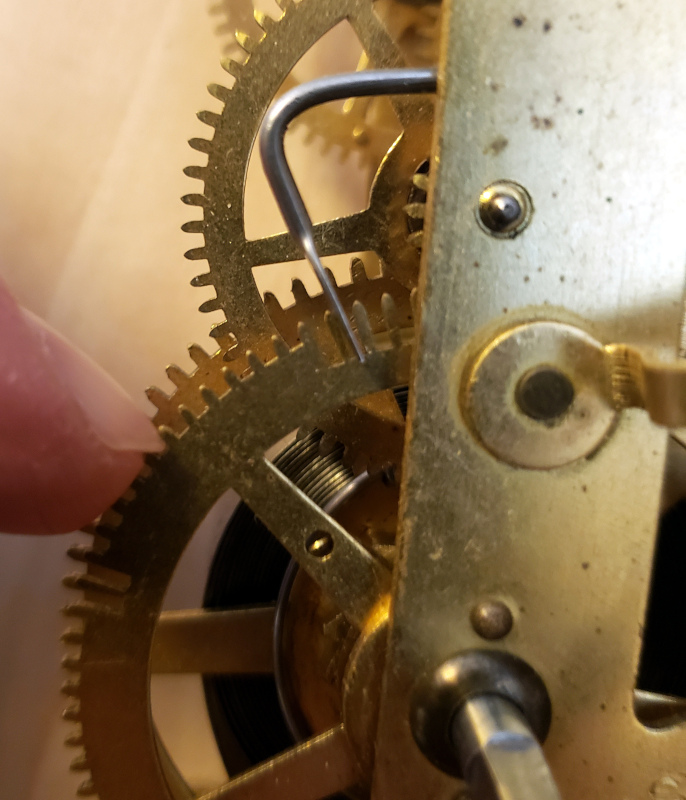

Notice a few things about the second photo: 1) that the count lever is against the left side of the slot rather than the right side, and 2) that the count lever runs the risk of hanging up on the left side of the slot.

The lesson from this observation about backlash: just before you adjust a count lever’s position, make sure that you’ve pulled or pushed the count wheel into its normal position (pushed clockwise in this clock). Otherwise when the clock runs the count lever will be in the wrong position relative to the slot it’s supposed to drop into.

From Steven Conover’s Clock Repair Basics book, I learned that a properly adjusted count lever end will point toward the center of the count wheel. As you can see from the photo above, the lever of this clock was pointing significantly above the center of the wheel. Which explains why the count lever wasn’t aligned well with the slots of the count wheel.

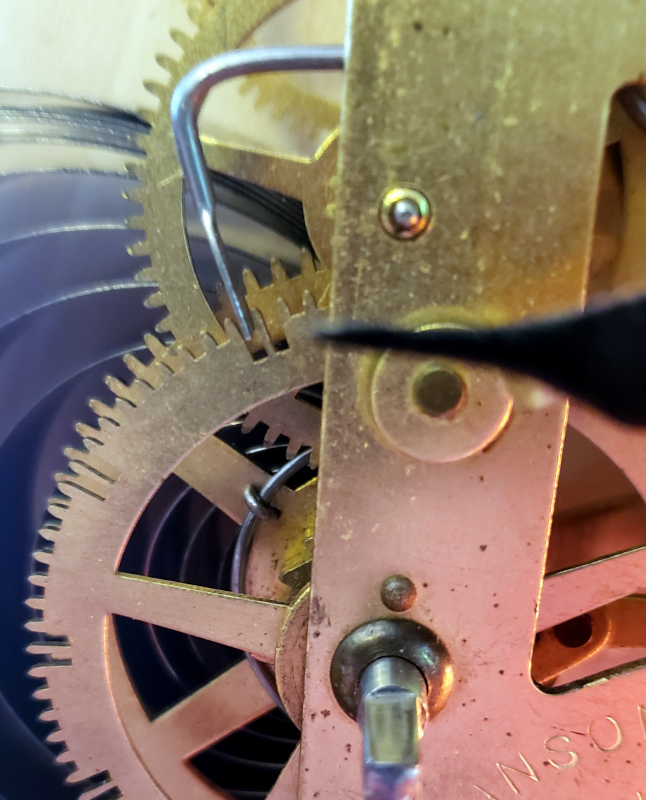

So I 1) let down the strike spring, 2) raised the count lever, then 3) very carefully bent the count lever to the left (outward) and curved the spade (the end) of the count lever to the right just a bit. With luck, this would center the end of the count lever in shallow and deep count wheel slots.

Aside from a bent tooth (see below), the adjustment went fine!

You can see that the adjustment seems correct: that whether the count lever is in a deep slot in the count wheel, a shallow slot in the count wheel, or raised and about to drop into a count wheel slot, the count lever nicely clears both sides of the count wheel’s slots.

The clock is now running on a test stand, to see whether I’ve really fixed the problem of it skipping counts.

Aside: a bent count wheel tooth

I thought I had been careful when bending the count lever, but I hadn’t been careful enough.

As you can see in the photo above, I’d bent a count wheel tooth. Those teeth are very delicate and easy to bend or break.

I carefully bent the tooth back into position, with – thankfully – no further problems. Whew!