I just now learned how the great wheels – the mainspring gears – work, by finding they didn’t work correctly in my Korean clock. The strike train Tension Washer, that is supposed to hold the gear firmly against the ratchet, has come loose. …so I had to disassemble the clock, after it had run fine for over 11 days.

In my previous post I had set the pendulum length, regulated (adjusted the speed of) the clock, and set it running for a 30-day test, to see whether its springs still run the clock for its full 31 days. If they don’t I’ll need to replace the springs.

I had to stop the test because I noticed the strike train great wheel gear had come loose from its arbor, risking the click letting the spring loose, which could damage the wheels – or worse, the hand of the person winding the clock when the click let loose.

So now I’ve disassembled the clock until I find out how to fix the problem.

How Mainsprings Wind and Unwind

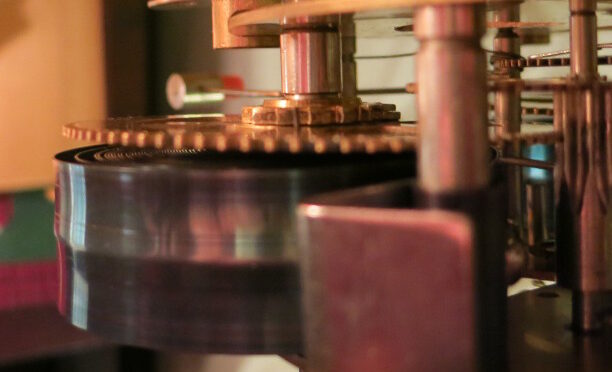

Take a look at the above image.

When you wind this wheel by turning a key you place on the end of the arbor, the arbor and ratchet turn – indicated by the smaller arrow – while the larger gear remains in place. That gear is held in place either by the escapement, in the case of the time train, or the lock, in the case of the striking or chime train. As you turn the winding key, the ratchet, which is fastened tightly to the arbor (center post) turns, clockwise in this image. As the ratchet turns clockwise, the click raises to let each tooth of the ratchet pass.

When you stop winding, the click falls back between the teeth on the ratchet, and the arbor and ratchet try to unwind, counter-clockwise in this image. The click keeps the arbor and ratchet from unwinding, and transmits all the force of the wound mainspring through the arbor and ratchet to the larger gear. That gear in turn transmits that force to the next gear in the train, which…. and so on.

So you can see that while winding, the arbor and ratchet turn and the larger gear doesn’t; while unwinding the arbor, ratchet, and larger gear all move together, as if welded into one piece.

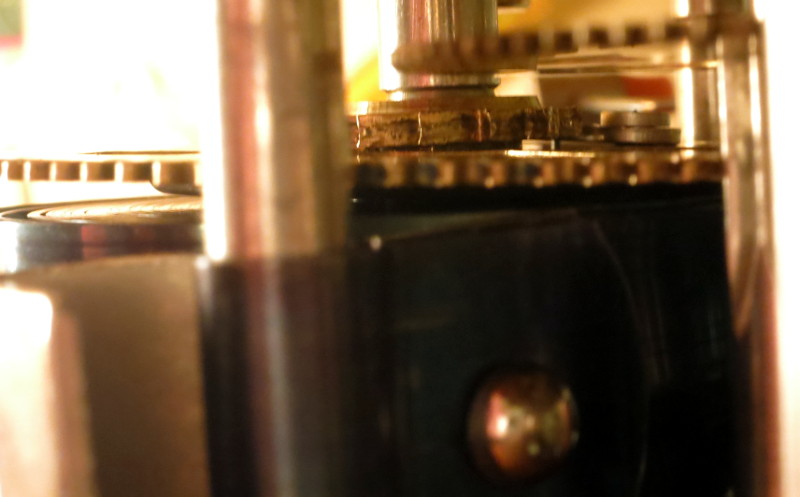

I never thought about that winding and unwinding, so I never realized that the larger gear is able to turn on the arbor. That gear is held down onto the ratchet by a “Tension Washer” – the grey disk in the back of the wheel in the image above. If the tension washer wasn’t there, the larger gear could tilt relative to the arbor, creating a gap between that gear and the ratchet. At worst, if that gap becomes large enough the click will fall into it instead of stopping against the ratchet, and the arbor and ratchet will spin out of control until the mainspring winds completely down.

After my Korean clock had been running for 11 days with no problems, I looked down into the works and saw a terrible gap in the strike great wheel, between that wheel’s ratchet and gear. It was about 1/2 the height of the click. If, as the mainspring unwound, the gear and mainspring tilted more, the click might let loose.

So I had to stop the 30-day-run test, disassemble the clock, and see what the problem is.

After comparing the strike train tension washer to the time train tension washer – which works fine, with no gap – I saw the problem: the strike train washer is bent and flattened so that it isn’t held in place by the ring on the arbor.

So I’ve ordered a clock-maker’s anvil, a set of stakes (rods with holes in their centers), and a riveting hammer. I already have a small ball peen hammer I use for 3D printing. Using these tools, I should be able to hammer the strike train tension washer back into shape. Then I should be able to reassemble the clock and start the 30-day run test again.

Until then my clock is in a set of jars: one for the tiny parts, one for the time train parts, and one for the striking train parts.

Update: Woohoo! Using the anvil, a ball peen hammer, a riveting hammer, and my thumbs, I was able to gently form the strike train great wheel tension washer back into shape. Then using a pair of snub-nose pliers, I – again gently – snapped it back into place. Score! Both great wheels are now snugly held onto their respective arbors by their respective tension washers.

I reassembled the clock, fully wound both of its mainsprings, then set it running on its 31-day run test at about 5 pm December 5th. If all goes well, it should still be going and striking on the evening of January 5th: Twelfth Night.