Having read Clifford Smyth’s excellent book, Functional Design for 3D Printing, I was anxious to try out his method of cutting a design into parts and gluing those parts together after printing.

One point he emphasized in his book is that (additive) 3D printed designs are far stronger in the XY plane than in the Z direction, and so it’s often best to print a design “sideways”, as separate parts that you glue together with Super Glue. He points out that fastening parts together with Super Glue takes only seconds, while removing support structures after printing can take a while (and can be a pain).

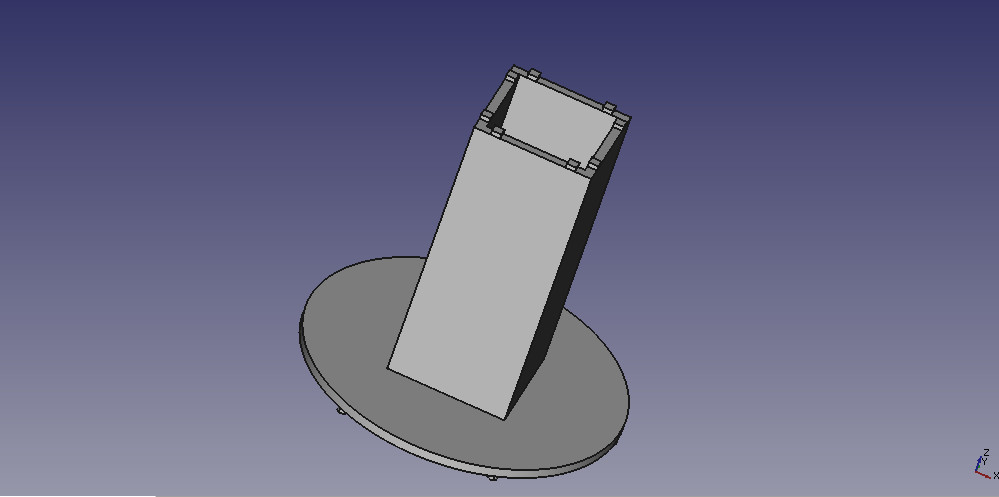

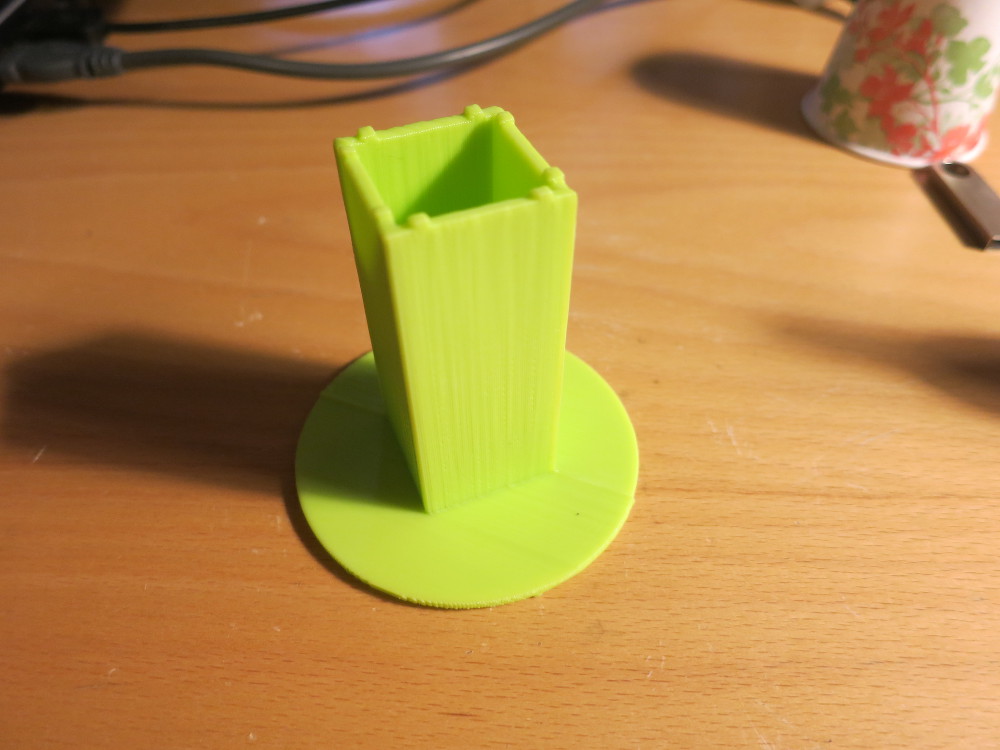

So I created a simple little stand for paper cups, to sit by the bathroom sink. It’s basically just a square tube with little knobs on the top, sitting on a disk that has similar little knobs on the bottom.

This particular design doesn’t benefit a whole lot from printing on its side, but it does benefit enough to try out the technique: if I printed the design as one, upright piece a couple problems would occur: 1) it would require a thin layer of support for the bottom disk, because the disk has knobs below it, 2) the knobs would break off easily, because the Z-axis binding of a 3D print is fairly poor, 3) the knobs on the lower disk would likely pull off when I removed the support structure.

So I cut the design into two parts, printed the parts on their sides, then glued the two parts back together. Here’s how I did it:

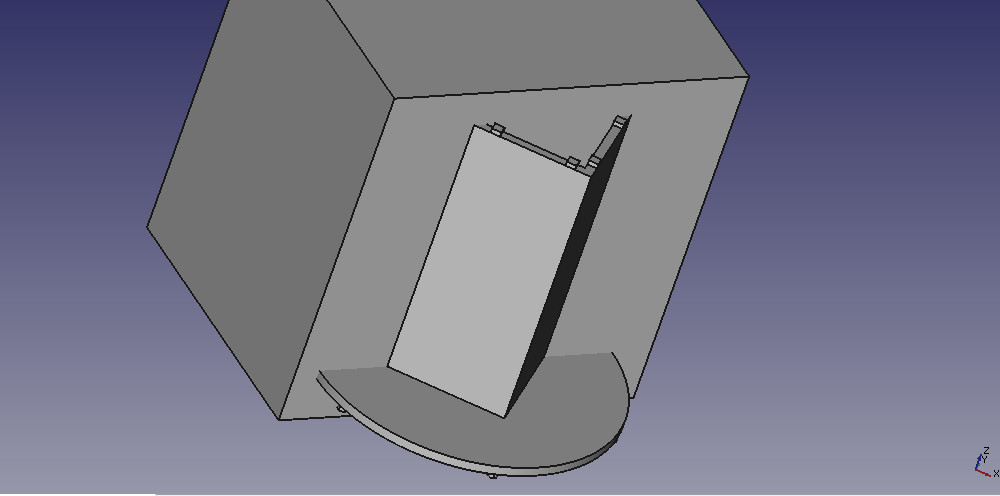

First, I created a block I’ll use to cut the design in half vertically.

In FreeCAD I subtracted the block from the design to create one of the two halves of the print, then I created a similar block and subtracted it from the original design to create the other half to print.

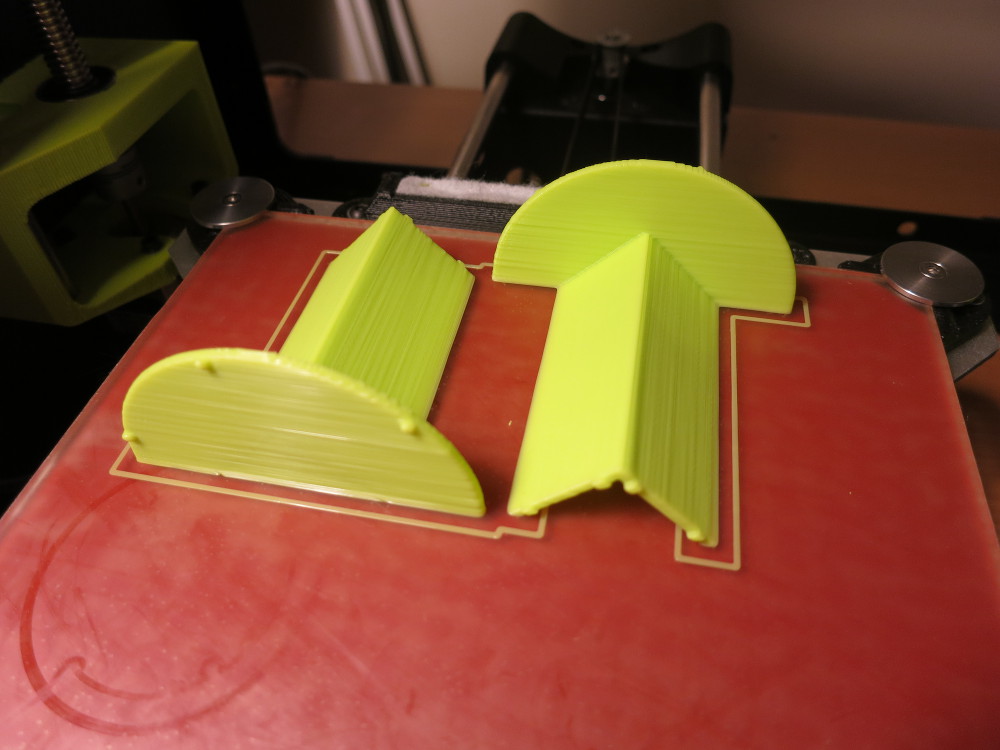

Here are the two halves, ready to come off the printer:

Note how a square tube, cut diagonally, produces a part whose sides are at 45 degrees from vertical – which happily happens to be the maximum angle many 3D printers can print without support. So the cut parts have absolutely no support to remove.

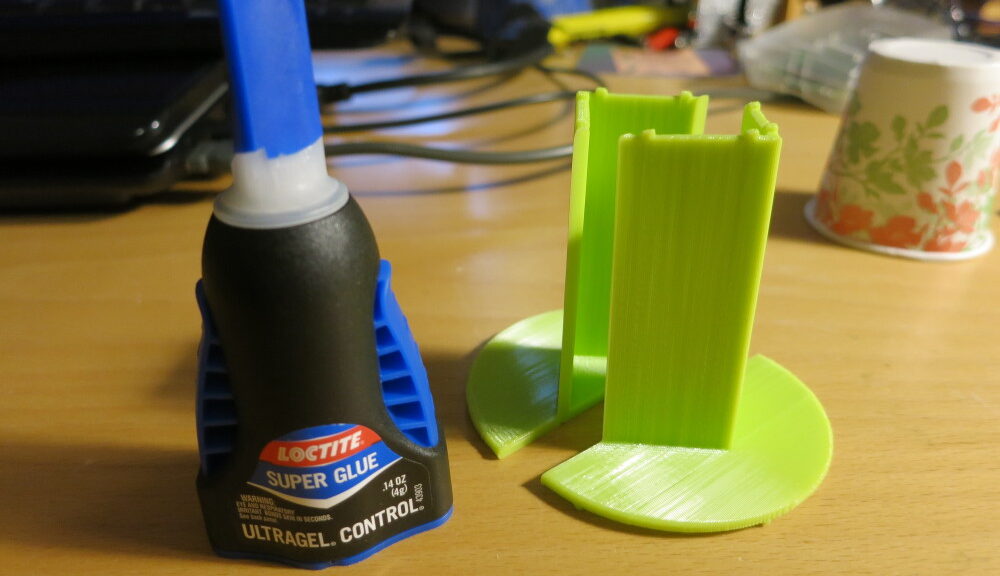

Let me reiterate that point Clifford Smyth makes in his book: it takes only 15 seconds or so to glue two printed parts together with Super Glue, while it can take a lot more time and more risk to your fingers (if you have to use a hobby knife) to remove support plastic.

My verdict: hey, this technique works really well!

P.S., In case you’re curious, here’s what the printed paper cup stand looks like. It’s basically a cheap paper cup dispenser – and non-food-safe by the way.

Update: I’ve now switched to E6000 as my favorite glue for PLA. I found Super Glue didn’t work very well on rough surfaces. In contrast, E6000 worked great.