In my previous post I calculated the theoretical length of the pendulum my Korean 30-day clock requires. You may recall that the clock as I bought it had a broken pendulum suspension spring, and the pendulum parts – the suspension rod and bob – were missing. In this post I order replacement pendulum parts.

Continue reading Clock Repair 101: Ordering Replacement PartsCategory Archives: Clock Repair

Clock Repair 101: Making Sense of the Time Gears

In my previous post I finished cleaning my Goodwill clock, ending up with a jumble of gears and other parts. You may recall that when I disassembled this clock, parts sort of fell out willy-nilly, leaving me a bit fuzzy about what gears go where. In this post, I figure out which gears are part of the Going (time) Train (gear set), and as a bonus I calculate the length of pendulum this clock requires.

Continue reading Clock Repair 101: Making Sense of the Time GearsClock Repair 101: I Finished “Cleaning” the Clock

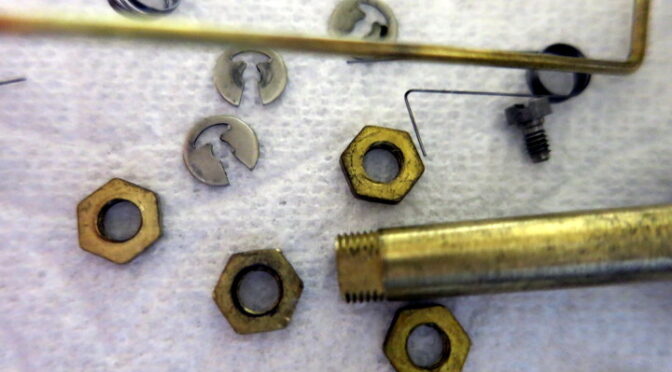

In my previous post I showed the early results of my cleaning of my Goodwill clock by hand. In this post I show why cleaning by hand isn’t really very effective at removing old oil and dirt.

After a few hours of scrubbing parts with SOS pads and toothbrushes, then rinsing in water – twice to get all the soap scum off – then rinsing in alcohol (wearing gloves this time), the clock parts are all “clean”.

Continue reading Clock Repair 101: I Finished “Cleaning” the ClockClock Repair 101: Cleaning (or Something Approaching It)

In my previous post, I disassembled my Goodwill, practice clock. In this post, I begin to clean it. The pro’s use an ultrasonic cleaner, but I’m on a budget, so I’m doing it by hand.

Update: I’ve learned a lot since I wrote this blog. See Update at the end of this post.

Continue reading Clock Repair 101: Cleaning (or Something Approaching It)Clock Repair 101: Disassembly / Destruction

In my previous post I covered the dangers of mainsprings, and bought the minimum of tools required to safely handle mainsprings. In this post I disassemble my junker clock.

Continue reading Clock Repair 101: Disassembly / DestructionClock Repair 101: a Time Bomb Waiting to Go Off

In my previous post I explained how I got started on this strange path to clock repair. In this post I talk about the dangers, some videos, and my first clock repair tools.

The first thing I did was to remove my Goodwill clock’s movement from the case. This step is pretty easy: unscrew the nut holding the hands on, gently pull the hands off, unscrew the wood screws holding the face onto the clock and voila, there is the movement.

Continue reading Clock Repair 101: a Time Bomb Waiting to Go OffClock Repair 101: “Lasciate ogne speranza, voi ch’intrate”

The Dark Arts of clock repair open before me. I feel the need to wear flannel. …to create a basement workshop. …and to live where it snows most of the year. What brought this malady on? A clock.

I have an old Seth Thomas “Chicago” series mantel clock that I believe belonged to my paternal grandparents, who were married in 1909. I haven’t run it for years, and got it into my head that it needed repair.

Continue reading Clock Repair 101: “Lasciate ogne speranza, voi ch’intrate”