Formula 409 turned out to be, as people had suggested, a fine way to clean the packing grease (likely Cosmoline) from the drill press parts. It’s necessary to clean this goo off so that 1) you don’t get it on the wood you’re working with, and b) the drill chuck doesn’t fall off while working (!)

Continue reading The Drill Press is DrillingMy First Real Machinery Arrives

The drill press arrived this evening!

I’ve never assembled a machine tool before, so I was put off by the rust-preventive coating that needs to be cleaned off, through mysterious and inadequately-explained means.

Continue reading My First Real Machinery ArrivesA Bit of the Mechanics of the Lunar Clock

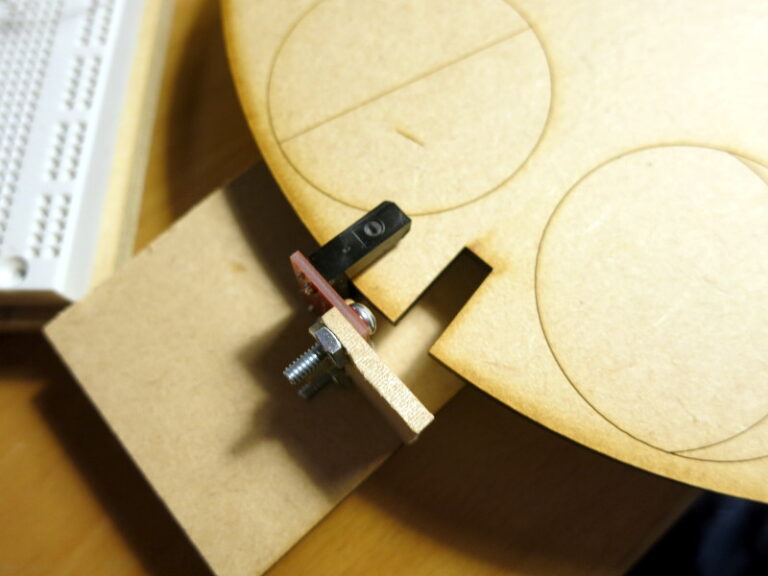

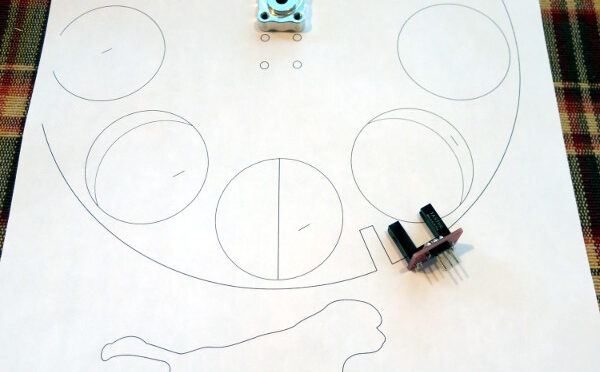

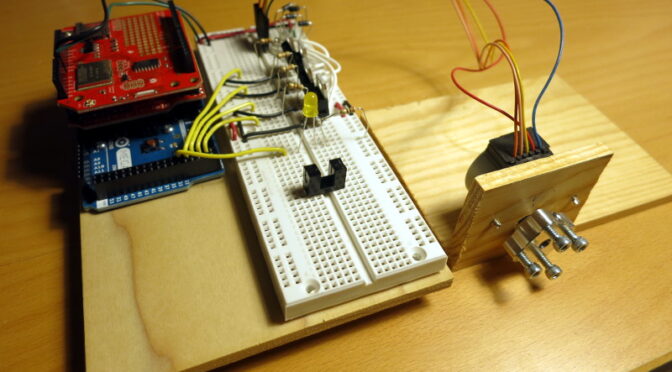

I’ve been doing a bit of mechanical work on the lunar clock, that I started in my previous post.

As a prototype to help me design the laser-cut parts, I cut out a strip of 1/8″ MDF, cut a square for the motor’s shaft and two holes for the motor mounting holes, then mounted the motor to that strip of wood.

Continue reading A Bit of the Mechanics of the Lunar ClockUnboxing My First Ponoko Shipment

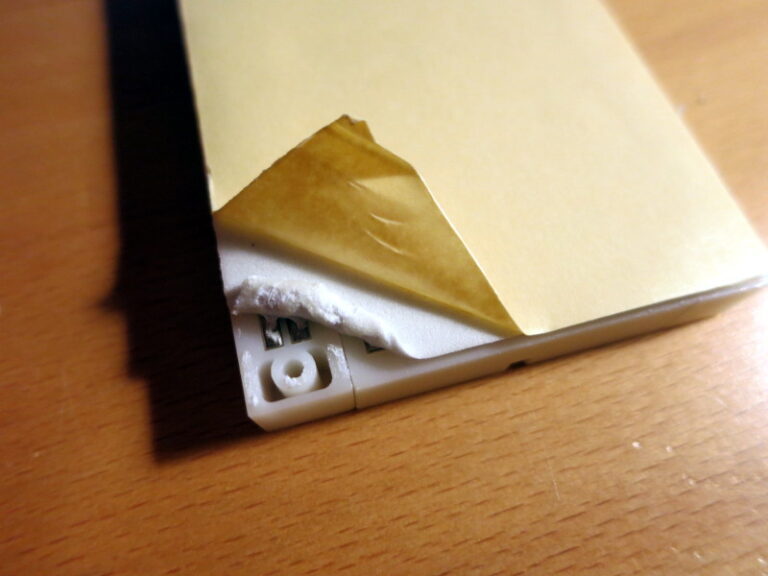

A short time ago I excitedly received my very first shipment from the laser cutting service Ponoko. Here’s a narrative of the unboxing, to let you know all the lovely details.

Continue reading Unboxing My First Ponoko ShipmentThe Hidden Mounting Holes in Your Breadboards

I’ve stored my Robotic Glockenspiel on its side since I finished it in April (it’s huge). The other day I opened the lid and found, to my horror, that the breadboard had completely pulled away from its adhesive pad – only the wires are keeping the breadboard from falling off completely!

Continue reading The Hidden Mounting Holes in Your BreadboardsMy First Laser Cutting Order Ever

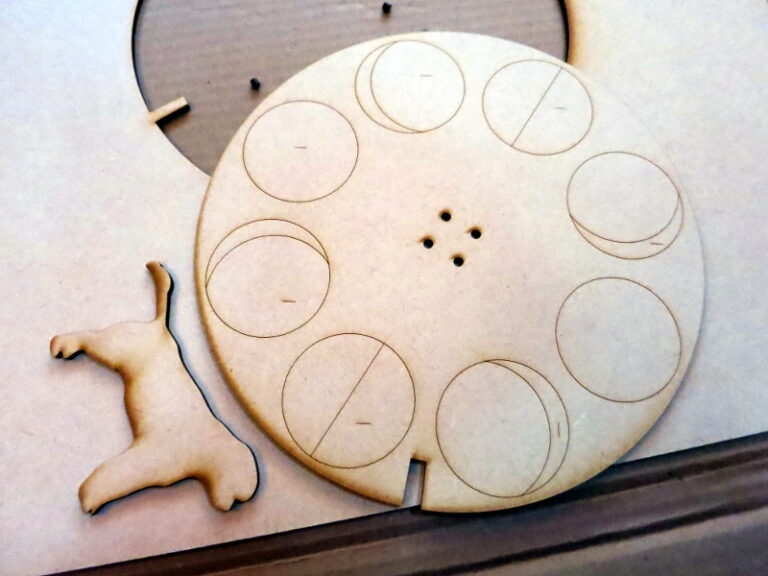

I’m delighted at how well the lunar clock is going! While waiting for stepper motors to arrive, I’ve been using Inkscape to create the laser-cutting pattern for the wheel that will contain images of the various phases of the moon. After a few hours of stumbling around (I’d never used Inkscape), I was drawing circles, arcs, and lines with abandon.

Continue reading My First Laser Cutting Order EverWiFi and Steppers and Slots! Oh, My!

The Lunar Clock project is starting to feel real!

After having no luck making the ESP8266 work with an Arduino Mega, I switched back to the wonderful Sparkfun CC3000 WiFi Shield. It is playing nice with the Mega now – with an interposed Sparkfun TransmogriShield to convert the Mega SPI pins to the Uno pins that many Shields expect. Update: I replaced both these retired boards in a later post.

Continue reading WiFi and Steppers and Slots! Oh, My!Started Work on a Lunar Clock

Last night I’ve started in earnest on a Lunar Clock project: a gizmo to physically display the current phase of the moon.

I say “in earnest” because I’ve created a GitHub repo for it, and a repo for the main library it uses. I wrote a (since obsoleted) library to filter out ESP8266 WiFi Shield messages from the text returned in an HTTP Response.

Continue reading Started Work on a Lunar ClockThe Robotic Glockenspiel is Complete!

After putting the finish on the wooden Glockenspiel case, I reassembled all the electronics, mechanics, and the box hardware (hinges, etc.). It works great! See my Arduino Robotic Glockenspiel Complete Demonstration video.

Ok, I still want to adjust the amount of silicone on each solenoid, to smooth out the sound, eliminating the clanking on all the chimes…but that’s for later.

As a reminder: the sources for the Glockenspiel are on the Glockenspiel Github site.

Adding a Finish to the Glockenspiel Case

Previously I finished the labels for the glockenspiel. In this post I literally Finish the case.

Last weekend and this weekend are nicely warm enough, so I’ve put a few coats of Minwax gloss polyurethane finish on the Robotic Glockenspiel case. In a few days the finish will be dry, and I can do the final fine-sanding (to remove dust captured in the Finish) and assemble the thing.

Continue reading Adding a Finish to the Glockenspiel Case