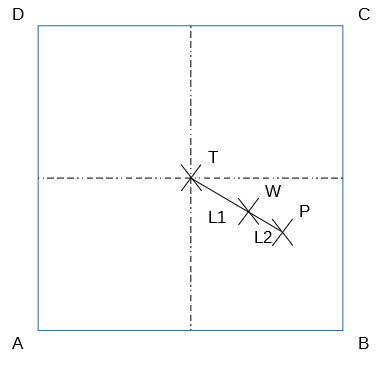

In my previous post I found the center of gravity of the top plywood circle of the Dog Bed Weight Scale. This post goes through the math of calculating the weight W on the scale and the position {X, Y} of that weight’s center of gravity. That is, how much does our dog PIppa weigh when resting on the bed, and what is her position on the bed?

Continue reading Dog Weight Scale Part 6: Calculating the Dog’s Weight and PositionDog Weight Scale Part 5: Center of Gravity and a Mounting Fail

In my previous post I described how to calibrate a load sensor. This post shows how to measure center of gravity, and shows a failed attempt to mount the load sensors to the scale.

Now that I’m using 4 load cell amplifiers rather than 1, I can calibrate each load sensor separately. This in turn will let the Arduino calculate Pippa’s real weight accurately regardless of what part of her bed/scale she’s lying on.

Continue reading Dog Weight Scale Part 5: Center of Gravity and a Mounting FailDog Weight Scale Part 4: Calibration and its Difficulties

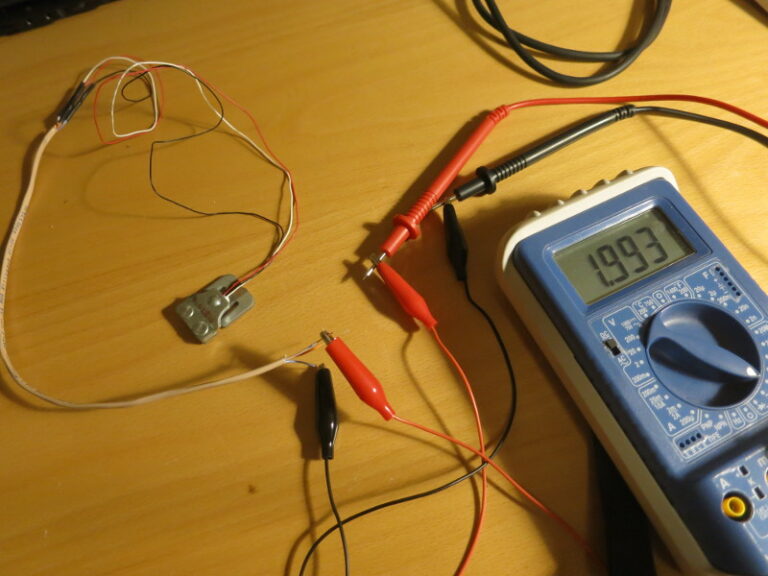

In my previous post I finished assembling the Dog Bed Weight Scale, at least enough to allow testing it. In this post, I relate how I calibrated and tested it.

Using the Bogde HX711 Load Cell Amplifier library and examples, and the Sparkfun HX711 Example Arduino Sketches, I quickly wrote a little Sketch to output the raw value from the scale (SCALE = 1.0 and OFFSET = 0L). The library made talking to the HX711 trivial.

Continue reading Dog Weight Scale Part 4: Calibration and its DifficultiesDog Weight Scale Part 3: the Woodworking and Assembly

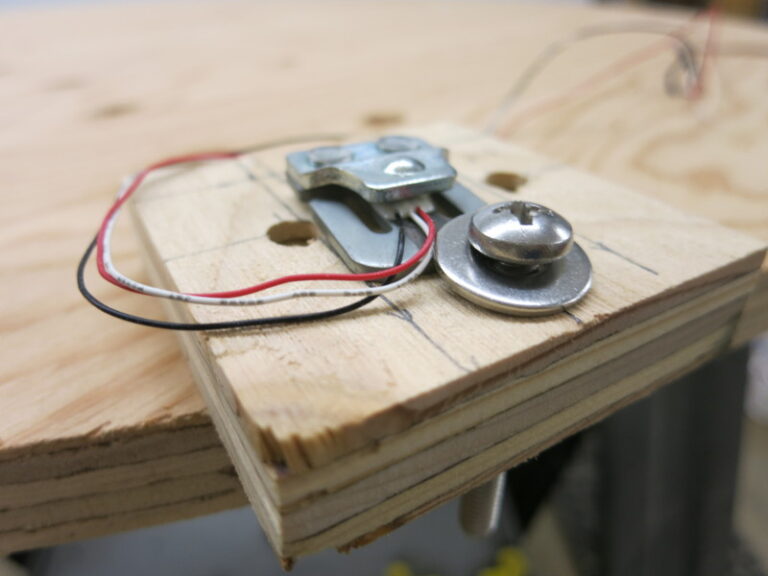

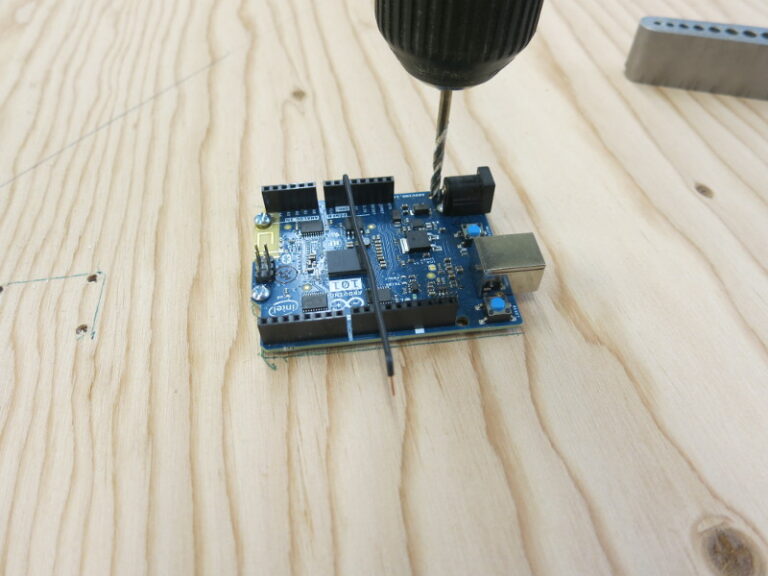

In my previous post I described the electronics of the Dog Bed Weight Scale. In this post, I’m doing the final woodworking and assembly – at least enough assembly to test the thing.

Continue reading Dog Weight Scale Part 3: the Woodworking and Assembly5 Things Project Runway Taught Me

I started watching Project Runway years ago as a guilty pleasure. My wife had watched it for a while and slowly drew me in because, unlike other reality/survivor shows, it minimized the People Behaving Badly aspect of competition.

As I watched more and more – the show has run more than 17 seasons at this point – I realized that Project Runway is really a show about how to do creative work and live the creative life. It even won a Peabody Award for using the Reality genre to inform and enlighten.

Continue reading 5 Things Project Runway Taught MeDog Weight Scale, Part 2: the Electronics

As I said in the previous post, I’m using 4 Sparkfun load sensors, a Load Sensor Combinator board, a Load Cell Amplifier board, and an Arduino 101 (since obsoleted) to build a scale I can put under our dog’s bed, to passively weigh her whenever she’s in bed.

In the previous post, I cut the base for the scale from a sheet of plywood. In this post, I’m assembling the circuit.

Continue reading Dog Weight Scale, Part 2: the ElectronicsDog Weight Scale, Part 1: Cutting the Circular Base

I want to learn how to use Load Sensors to continuously weigh stuff with an Arduino, so I thought it would be fun to continuously weigh our dog, Pippa, while she sleeps in her bed each night. The project is a little like Nate Seidle’s Beehive scale, but simpler.

The idea is to turn Pippa’s bed into a scale. Pippa’s in fine shape right now, but it’s always good to keep an eye on your dog’s weight, and a custom-made scale is a great way to do it.

Continue reading Dog Weight Scale, Part 1: Cutting the Circular BaseMy Newbie CSS Mistakes

Whew! I’ve been (re)learning CSS and have discovered a few newbie misconceptions of mine that had really held me back.

CSS = Cascading Style Sheets. In an ideal web app, the HTML defines the page structure, the CSS defines the presentation (look), and the JavaScript/jQuery defines the behavior.

Continue reading My Newbie CSS MistakesHow to Make a Drill Press Fence

After completing my drill press table, I decided my next step would be to make a fence for it – so I can drill vertical holes in the sides of short boards.

First I cut a 3 1/2″ board of 3/4″ MDF, of a width to match the drill press table. This first piece will be the face of the fence.

Continue reading How to Make a Drill Press FenceHow to Make a Drill Press Table

As multiple woodworkers have mentioned, a drill press as-is is poorly suited to doing woodworking: the cast iron table can transfer grease to the wood; the table is small; the table has limited places to fasten clamps to hold the wood down.

So here I am making a drill press table.

Continue reading How to Make a Drill Press Table