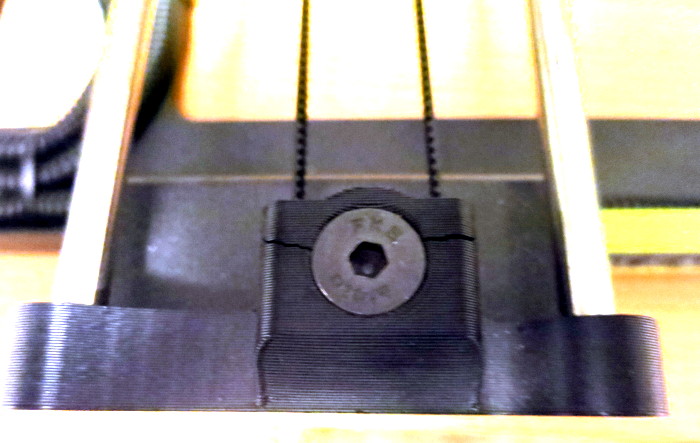

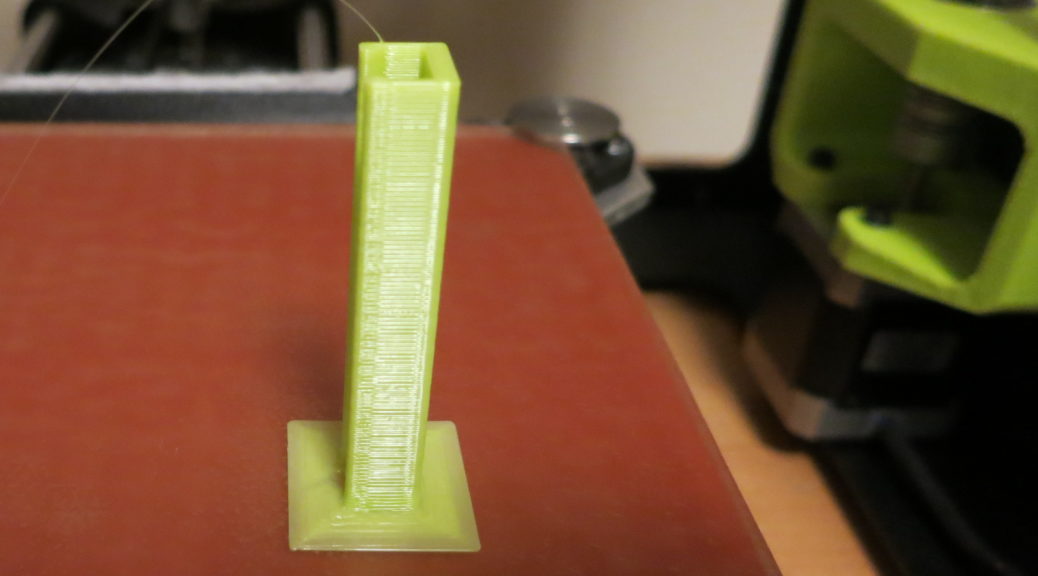

I used to think that 3D Printer extruder tension – how much pressure the extruder hobbed gear exerts on the filament to move it forward – was a pretty forgiving thing. At one extreme, there’s “so loose the filament doesn’t feed” and on the other, there’s “so tight the extruder motor binds”. I thought everything in between was ok.

My assumption was confirmed each time I read advice on how to tune a misbehaving printer: people rarely mentioned extruder tension.

My recent fight to fix a bad print taught me that incorrect extruder tension can make a huge difference in your print quality after all.

Continue reading Extruder gear tension: the overlooked adjustment →

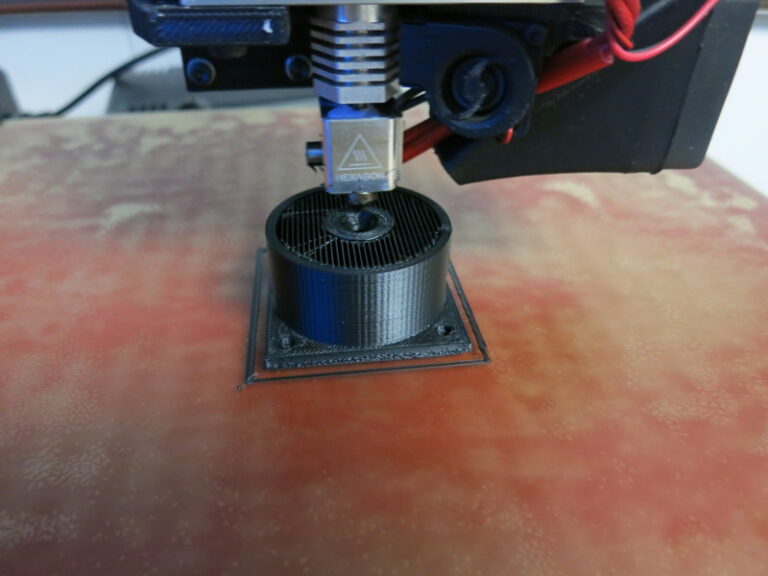

I bought my Lulzbot Mini 3D printer almost 2 years ago, and I’ve loved it. While I’ve read others’ troubles trying to get their kit 3D printers working, or calibrated, or repaired, or trying to get their prints to stick, or not stick… my little Lulzbot Mini has been chugging reliably along, printing accurate objects every time.

Now, inevitably, I have to admit my printer is showing its age, and that it’s time to get my hands dirty with a little maintenance.

Continue reading My 3D Printer is showing its age →

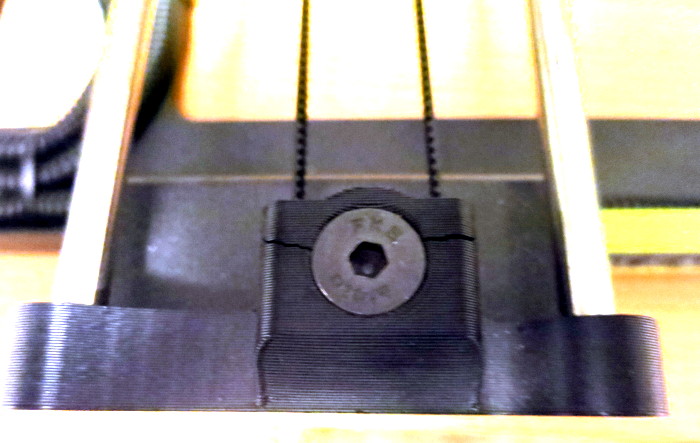

I’ve found 3D printing to be perfect for creating replacement parts for the various things that break around the house. Recently I realized that I could make a replacement for the armoire door clip that had been bent beyond recognition over the years. This post details how I designed and tested the 3D printed replacement, including a checklist at the end of this post.

Continue reading Designing a 3D printed cabinet clip replacement →

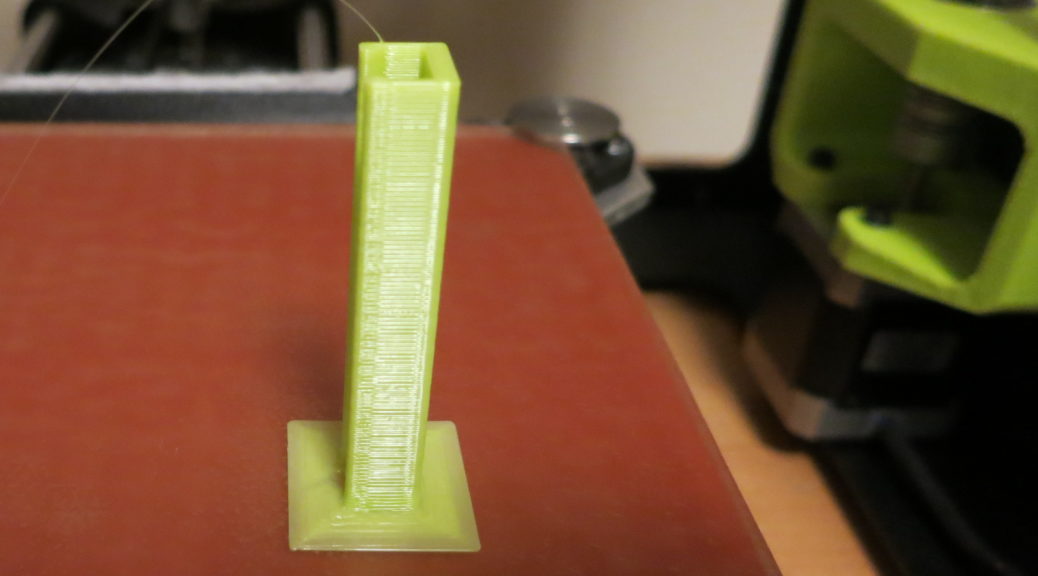

I’ve been designing 3d printed parts for a while now, and thought I had the process down to a science. Continue reading What is a Brim and why does my 3d print need one? →

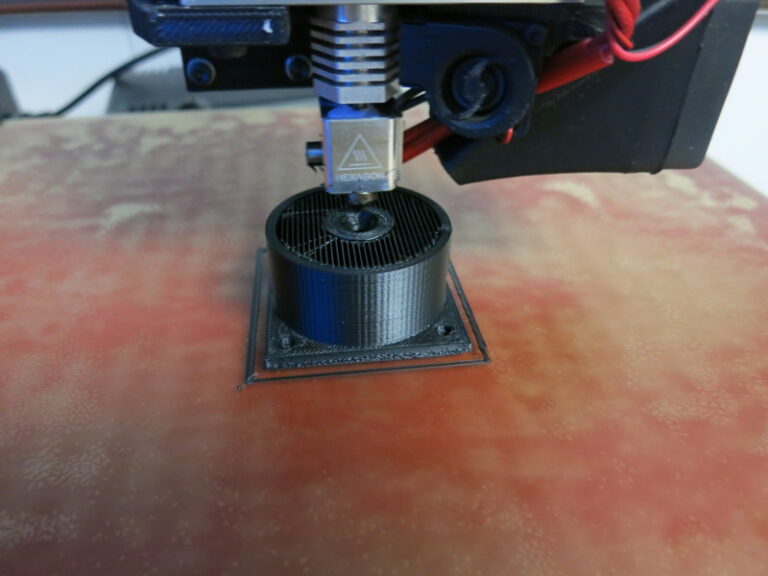

In my previous post, I did a little woodworking on the scale. In this post, I start designing a 3D printed part that will keep the top of the scale centered on the bottom.

Ever since I measured the center of gravity of the top plywood circle, I’ve been puzzling through how to make sure that center of gravity stays centered on the bottom part of the scale. Without some sort of connection between the top and bottom plywood circles, the top will inevitably slide over time, messing up all the center of gravity calculations. On the other hand, if this connection between the top and bottom has much vertical friction, it will take some of the load of the scale, throwing off the weight calculation.

Continue reading Dog Weight Scale Part 12: More 3D Printing →

Technical Writing and Self-Pubilshing