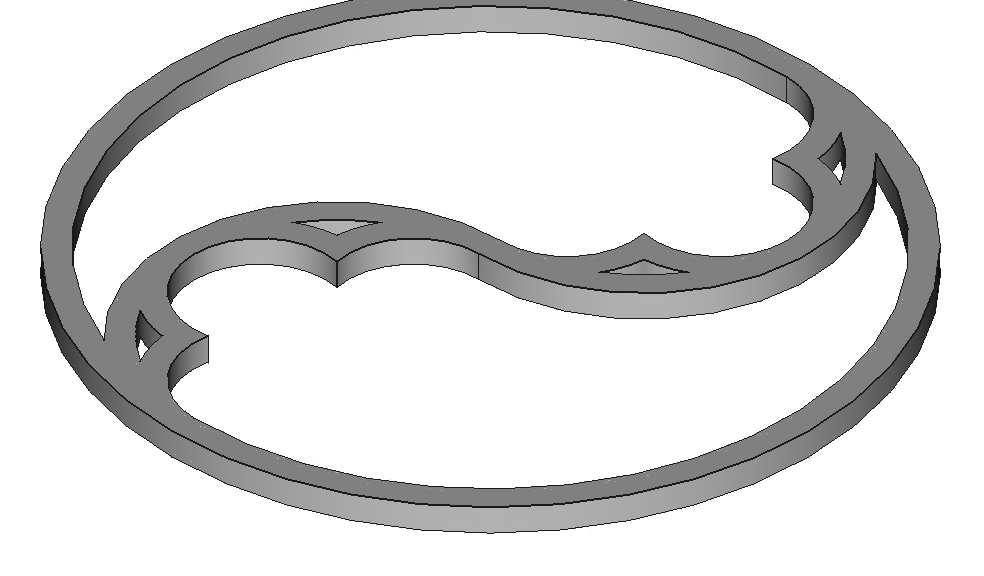

If you’re interested in Gothic architecture, you may have seen my post on Designing a Gothic Trefoil. In this post I walk you though the design in FreeCAD of a simpler ornament, the Gothic Duefoil: a circle divided into two arches, which are themselves each divided into three lobes.

Continue reading Designing a Gothic Duefoil in FreeCADDesigning a Gothic Duefoil in Fusion 360

If you’re interested in Gothic architecture, you may have seen my post on Designing a Gothic Trefoil. In this post I walk you though the design of a simpler ornament: the Gothic Duefoil: a circle divided into two arches, which are themselves each divided into three lobes.

Read moreChevy Bolt Tips

In January 2020 I started shopping for an electric car, buying a Chevy Bolt at the end of March. This post is a collection of the handy tips I’ve learned along the way.

Continue reading Chevy Bolt TipsChoosing and Buying an Electric Car

In January 2020 I started shopping for an electric car, buying a 2020 Chevy Bolt at the end of March. This post is a summary of the resources and methods I used to choose that car among the – happily – several likely electric cars on the market.

Continue reading Choosing and Buying an Electric CarCharging a 2020 Chevy Bolt Near Hillsboro Oregon

In January 2020 I started shopping for an electric car, buying a Chevy Bolt at the end of March. This post is a summary of what I’ve learned about charging the Bolt, both at home and on the road.

This is an evolving page about a rapidly evolving business. I’ll add more information as I learn it.

Continue reading Charging a 2020 Chevy Bolt Near Hillsboro OregonProgress on My Clockmaker’s Bench

In August I bought an old, 7-drawer student’s desk at a garage sale. Since then I’ve been converting it to a clockmaker’s bench. This note is a quick update; I plan to write a full, how-to booklet once I’ve completed it.

I learned amateur clock repairers often make their own benches, starting from a solid writing desk. I bought mine at a garage sale.

Continue reading Progress on My Clockmaker’s BenchAn American Version of Welsh Bara Brith Tea Bread

During our trips to Wales we found that every little tea room served a wonderful fruit bread called Bara Brith – literally “speckled bread”. Recently, after having a tough bout of Bara Brith withdrawal, I decided to make my own, by adapting the Welsh recipe to Metric-impaired Americans like myself.

Continue reading An American Version of Welsh Bara Brith Tea BreadRepairing a Clock Case’s Stripped Wood Screw Hole

I’m repairing a cuckoo clock that has a commonly-seen problem: one of the screws mounting the movement to the case has stripped its hole. Normally, I’d try filling the hole with a wood filler, but this time I tried something different: “Bushing” the hole with a plug of new wood.

In digging around for clock case repair advice, I found a wonderful book, Extreme Restoration by T.E. Temple, which covers many clock case restoration methods. Its section on repairing stripped nail and wood screw holes in clock cases inspired me to try using a wood plug to patch the stripped hole, because that author has found wood plugs to be an excellent long-term repair.

Continue reading Repairing a Clock Case’s Stripped Wood Screw HoleMy Clock Repairs So Far

Since I attended my first local chapter meeting of the NAWCC (National Association of Watch and Clock Collectors) I thought I’d make a quick gallery of the clocks I’ve worked on so far.

Continue reading My Clock Repairs So FarRepairing a Cracked Plastic Clock Gear

While repairing the latest musical cuckoo clock I discovered a problem in the musical movement: a cracked plastic gear. I was at a loss as to how this could be fixed, but once again found the solution from expert posts on the message boards at the NAWCC (National Association of Watch and Clock Collectors). The whole story follows…

Continue reading Repairing a Cracked Plastic Clock Gear