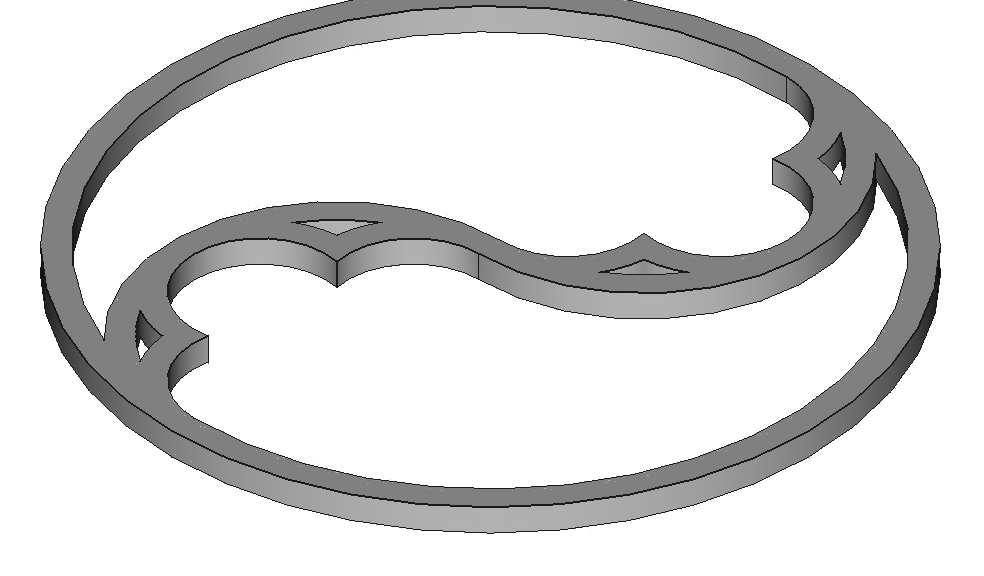

If you’re interested in Gothic architecture, you may have seen my post on Designing a Gothic Trefoil. In this post I walk you though the design in FreeCAD of a simpler ornament, the Gothic Duefoil: a circle divided into two arches, which are themselves each divided into three lobes.

Continue reading Designing a Gothic Duefoil in FreeCADCategory Archives: 3D Printing

Designing a Gothic Duefoil in Fusion 360

If you’re interested in Gothic architecture, you may have seen my post on Designing a Gothic Trefoil. In this post I walk you though the design of a simpler ornament: the Gothic Duefoil: a circle divided into two arches, which are themselves each divided into three lobes.

Read moreReplacing the Numbers on a Cuckoo Clock Dial

A while ago I bought a beat up cuckoo clock on eBay, to practice cuckoo clock cleaning and repair. Its face was missing most of its numerals. In this post, I describe how to use a 3D printed template to glue the numerals on a cuckoo clock’s face.

Continue reading Replacing the Numbers on a Cuckoo Clock DialPrinting replacement parts for your Prusa 3D printer

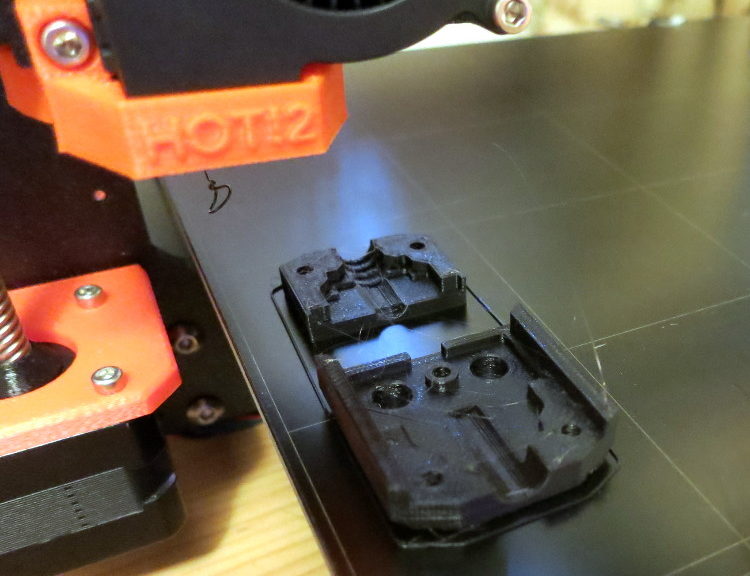

I recently bought and assembled a Prusa i3 MK3 kit, and decided to prepare for printing emergencies by printing a full set of replacement parts as soon as the printer was working well.

I’d found, in using my other printer, that even high-quality printed parts do eventually delaminate under stress: after two years, that printer’s X and Y idler supports developed fractures. Because I couldn’t print the replacement parts (and because doing the replacement seemed daunting at the time), I wound up sending that printer to the factory for repairs.

I’ve also seen notes and videos from people recommending a set of replacement parts as a backup, in case you break a part while adjusting or doing maintenance on your printer. Having replacement parts on hand is also a good preparation for helping a 3D printing friend when their printer breaks.

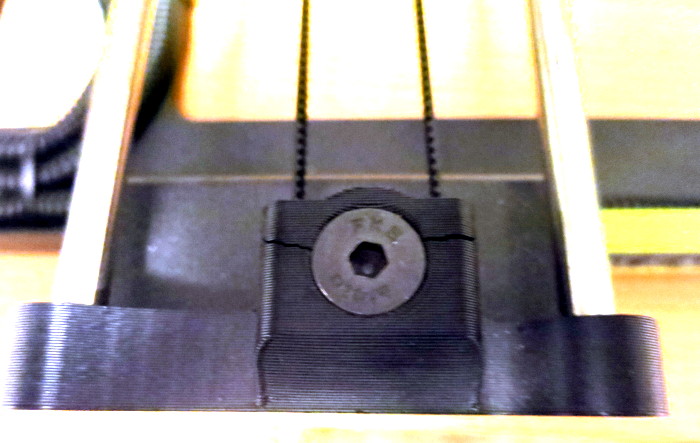

Continue reading Printing replacement parts for your Prusa 3D printerExtruder gear tension: the overlooked adjustment

I used to think that 3D Printer extruder tension – how much pressure the extruder hobbed gear exerts on the filament to move it forward – was a pretty forgiving thing. At one extreme, there’s “so loose the filament doesn’t feed” and on the other, there’s “so tight the extruder motor binds”. I thought everything in between was ok.

My assumption was confirmed each time I read advice on how to tune a misbehaving printer: people rarely mentioned extruder tension.

My recent fight to fix a bad print taught me that incorrect extruder tension can make a huge difference in your print quality after all.

Continue reading Extruder gear tension: the overlooked adjustment

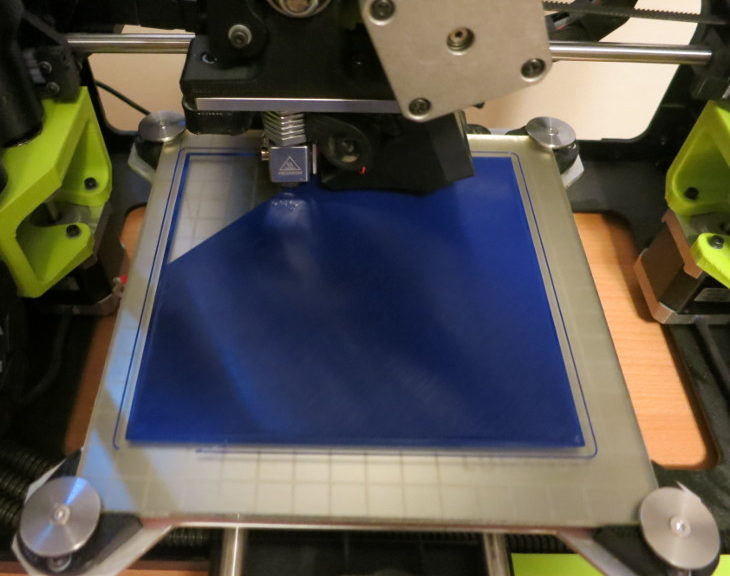

Testing Your 3D Printer’s First Layer Height Calibration

One of the last steps of assembling a Prusa i3 MK3 3d printer is to manually adjust the Z height. As I adjusted my printer’s Z height, I began to wonder what the Z height calibration looked like on my older printer, a Lulzbot Mini. At the same time, I became curious about what size that Lulzbot Mini can print. A simple test print answered both questions.

Continue reading Testing Your 3D Printer’s First Layer Height Calibration

Designing a Gothic Trefoil in FreeCAD

I’ve been interested in the Tracery in Gothic Cathedrals – the delicate patterns in stone walls and windows – for years. In this post, I show you how to design of one type of Gothic ornament, using FreeCAD. You can follow along with the FreeCAD file on Cults3D, or you can use your favorite CAD application, such as Autodesk Fusion 360.

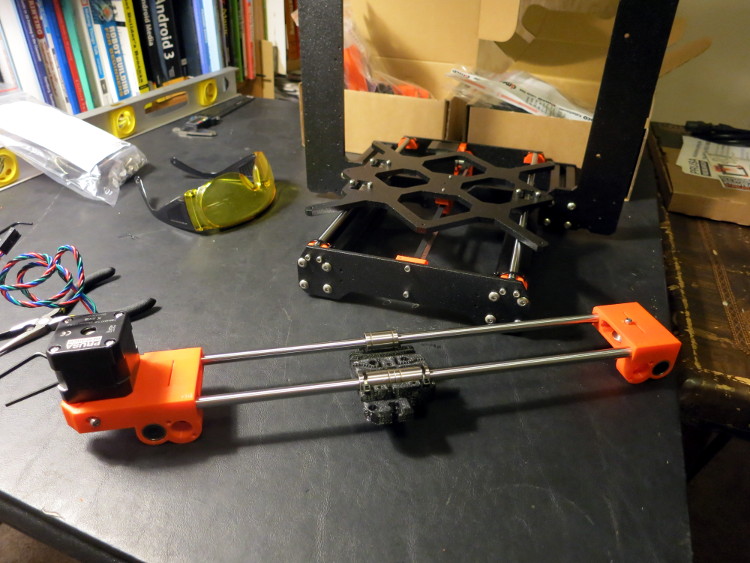

Tips for assembling the Prusa I3 MK3 Kit

Having just spent 24 hours, spread over 4 days, assembling a Prusa I3 MK3 Kit, here are my notes to help you assemble your own kit.

My 3D Printer is showing its age

I bought my Lulzbot Mini 3D printer almost 2 years ago, and I’ve loved it. While I’ve read others’ troubles trying to get their kit 3D printers working, or calibrated, or repaired, or trying to get their prints to stick, or not stick… my little Lulzbot Mini has been chugging reliably along, printing accurate objects every time.

Now, inevitably, I have to admit my printer is showing its age, and that it’s time to get my hands dirty with a little maintenance.

Designing 3d printed threads to match existing parts

I often 3D print screw-top parts to replace broken or missing parts. For example, we recently installed media (blackout) shades for our skylights, so we can watch movies when the sun is out. Our family room ceiling is quite high, so the pole and hook designed to open and close the new shades is too short.

Continue reading Designing 3d printed threads to match existing parts