In my previous post I finished cleaning my Goodwill clock, ending up with a jumble of gears and other parts. You may recall that when I disassembled this clock, parts sort of fell out willy-nilly, leaving me a bit fuzzy about what gears go where. In this post, I figure out which gears are part of the Going (time) Train (gear set), and as a bonus I calculate the length of pendulum this clock requires.

Continue reading Clock Repair 101: Making Sense of the Time GearsTag Archives: Maker

Clock Repair 101: I Finished “Cleaning” the Clock

In my previous post I showed the early results of my cleaning of my Goodwill clock by hand. In this post I show why cleaning by hand isn’t really very effective at removing old oil and dirt.

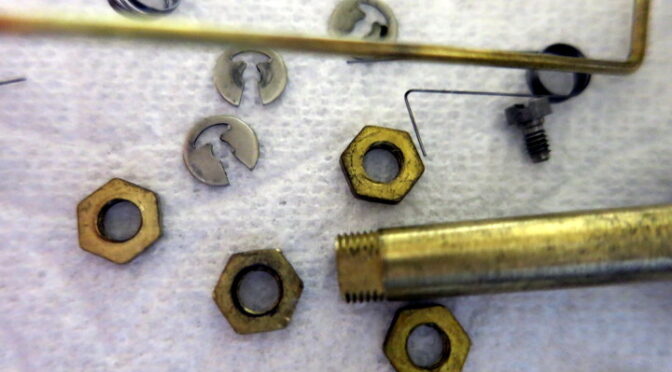

After a few hours of scrubbing parts with SOS pads and toothbrushes, then rinsing in water – twice to get all the soap scum off – then rinsing in alcohol (wearing gloves this time), the clock parts are all “clean”.

Continue reading Clock Repair 101: I Finished “Cleaning” the ClockClock Repair 101: Cleaning (or Something Approaching It)

In my previous post, I disassembled my Goodwill, practice clock. In this post, I begin to clean it. The pro’s use an ultrasonic cleaner, but I’m on a budget, so I’m doing it by hand.

Update: I’ve learned a lot since I wrote this blog. See Update at the end of this post.

Continue reading Clock Repair 101: Cleaning (or Something Approaching It)Clock Repair 101: Disassembly / Destruction

In my previous post I covered the dangers of mainsprings, and bought the minimum of tools required to safely handle mainsprings. In this post I disassemble my junker clock.

Continue reading Clock Repair 101: Disassembly / DestructionClock Repair 101: a Time Bomb Waiting to Go Off

In my previous post I explained how I got started on this strange path to clock repair. In this post I talk about the dangers, some videos, and my first clock repair tools.

The first thing I did was to remove my Goodwill clock’s movement from the case. This step is pretty easy: unscrew the nut holding the hands on, gently pull the hands off, unscrew the wood screws holding the face onto the clock and voila, there is the movement.

Continue reading Clock Repair 101: a Time Bomb Waiting to Go OffClock Repair 101: “Lasciate ogne speranza, voi ch’intrate”

The Dark Arts of clock repair open before me. I feel the need to wear flannel. …to create a basement workshop. …and to live where it snows most of the year. What brought this malady on? A clock.

I have an old Seth Thomas “Chicago” series mantel clock that I believe belonged to my paternal grandparents, who were married in 1909. I haven’t run it for years, and got it into my head that it needed repair.

Continue reading Clock Repair 101: “Lasciate ogne speranza, voi ch’intrate”Geometry, Gothic Architecture, Rose Windows, and Christmas Ornaments

(first published on Needhamia.com in 2007)

I find the rose windows of Gothic cathedrals awe-inspiring. From the rigid formalism of Chartres to the flamboyant explosion of Tours, their marriage of geometry, philosophy, and aesthetics with stone and glass is awesome. Built at a time when science and spirit weren’t as divided as today, each window is a statement of the beauty, order, and harmony in the world. Using only a pair of compasses (dividers) and a straight-edge (an unmarked ruler), the Gothic architects created myriad lace-like designs, making stone hang in the air and glass sing.

Continue reading Geometry, Gothic Architecture, Rose Windows, and Christmas OrnamentsBuild a Minimal Weather Underground Station

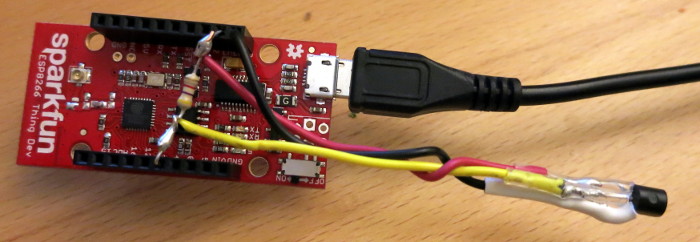

Today’s post is a How-To for a project I recently completed: a temperature-only Weather Underground Personal Weather Station made from an ESP8266, a MAX31820 temperature sensor, and a few miscellaneous parts. The whole project fits inside a 3D printed project box for mounting on an exterior wall that is sheltered from the weather.

The open source project files are in my MAX31820WeatherStation Github repository.

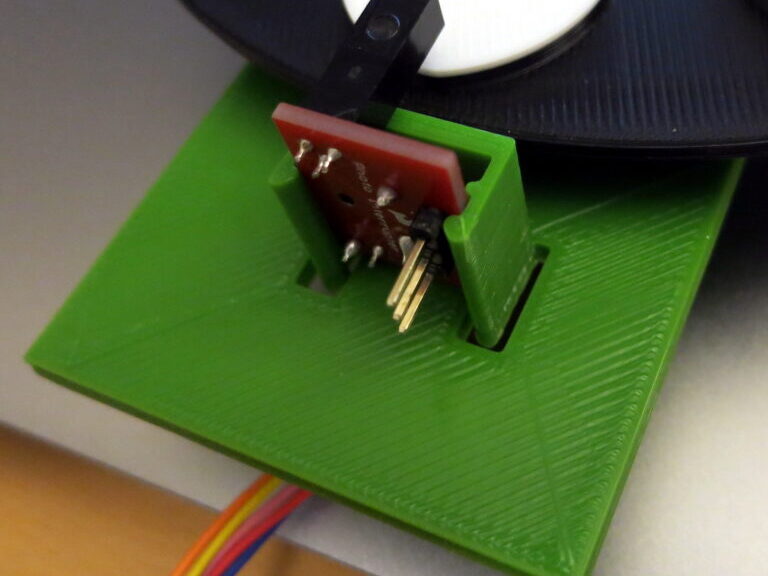

Continue reading Build a Minimal Weather Underground StationLunar Clock: Designing a 3D Printed Clip

In my previous post, I replaced the electronics of my several-year-old lunar clock design with modern parts. In this post, I’ve replaced the laser cut parts with 3D printed parts, with particular attention to the clip that holds the photo interrupter in place.

Continue reading Lunar Clock: Designing a 3D Printed ClipWell Depth Sensing: Soldering, Soldering, Soldering!

In my previous post, I designed a 3D printed sensor junction box for my well tank depth sensing project. In this post I solder… a lot.

I have 36 RJ45 jacks, 36 breakout boards for those jacks, and a pile of break-off headers for those breakout boards. Each breakout board has 8 holes for the RJ45 jack pins and 8 more holes for the header pins. That’s 36 * (8+8) connections I need to make to attach the breakout boards to the jacks. That’s 576 connections to solder!

Continue reading Well Depth Sensing: Soldering, Soldering, Soldering!